|

|

|

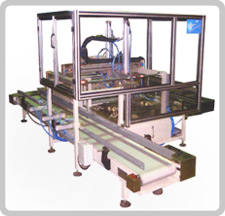

Case Packer Series

Single Head Case Packer - (ACP-PPS-Series)

- The machine works on the principle of pick and place method using specially designed vacuum suction systems.

- Cycle Speed : Pneumatically operated : 12 cycles / head and Servo Driven : l5cycles / head.

- Matrix Plate : Matches to the carton size. matrix and product size fitted with rectangular bellow suction cups or round bellow suction cups depending upon the product shape.

Double Head Case Packer - (ACP-PPD-Series)

- PLC : Allen Bradley make with HMI panel optional extra & pneumatic components are of FESTO / SMC make.

- The machine houses the electrical and pneumatic panel within the base foot print of the machine.

- Grippers are used to hold containers and bottles if they are not suitable for lifting through vacuum.

Four Head Case Packer - (ACP-PP-TWH-DUP-Series)

- All moving parts are covered with safety limit switch interlock and the machine is fitted with optional beam sensors (Light curtains) to ensure operator safety.

- HMI will display trouble shooting procedures and fault indications to minimize down time and improve OEE. Coverall equipment efficiency.

- Electrical and pneumatic components are designed for easy access and replacement without disturbing main wiring system to reduce down time.

High Speed Servo Model

- Predominantly pneunmatically operated case packer models are used because of the user friendliness and cost effectiveness

- However to achieve more cycle speed SERVO driven machines are supplied depending upon customer requirements.

- Allen Bradley SERVO drives are used

- 25% increased cycle speed may be achieved by using SERVO based case packing system

- ROBOTIC pick and place systems may also supplied by us through integrating standard ROBOT to our case packer models

Modular Belt Matrix Base Model - (ACP-PP*-MD-Series)

- The modular belt matrix base models helps in achieving higher speeds.

- It is difficult to arrange certain products on matrix table. Modular belts enable inline matrix formation for such products.

- Design of such machinery are tailor made to match the specific requirement of customers.

|

|

|

Case Erector Cum Packer Mono Block Series

Auto Case Erector - Filling-Taping Model

- The mono block case erector cum packer model combines the operation of both carton opening and product filling to final taping.

- Carton bundles loaded in the magazine are erected automatically and fed to the filing station.

- The product is filled in to the carton through suitable method matching to product nature and orientation for filling.

- After filling both top and bottom flaps are closed and taping is done or fed to the final end of line conveyor.

- Consistency in the quality of carton plays a major role when auto carton erection is integrated.

|

| |